Friday, July 13, 2018

Improving Tomix "Second Generation" mechanisms

Older Tomix N gauge trains are infamous for their "spring worm" drive mechanism, whereby the motor is connected to the bogie gear tower via a long spring-like metal spiral. While presumably cheap to manufacturer, it does result in somewhat noisy operation, so from the late 1980s (IIRC) Tomix gradually phased this out in favour of a more conventional mechanism with cardan shafts connecting to a worm gear on top of the bogie gear tower. This second generation does however seem to have retained the older electrical pickup mechanism, with copper forms pressing down on the axles inside the wheels (similar to what Lima did, e.g. on the Class 31), which is more reliable than wiper-based pickups but not as elegant as current axle pinpoint pickups.

Anyway, while this second generation of Tomix mechanisms is basically robust and reliable, some can be surprisingly noisy. I'm not sure whether that was the case when they were new, or whether something's deteriorated with age, but certainly annoying on otherwise decent models.

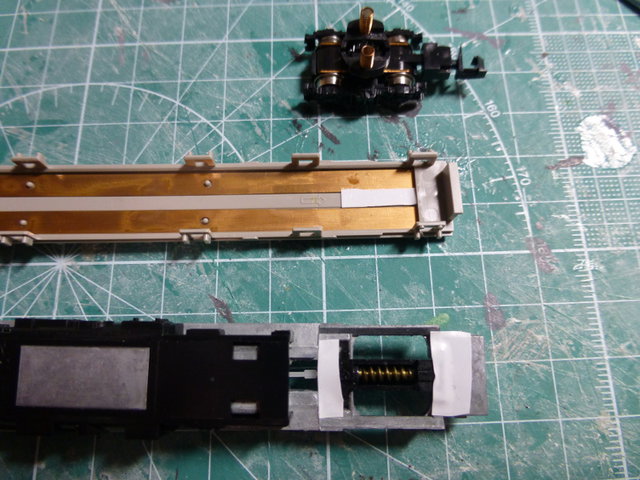

After some investigation it seems a common issue is that the worm gear case is slightly loose and prone to vibrating against the chassis. This can be mitigated by applying strips of electrical tape to hold it in place, as seen here on an older Tomix 115-1000 series:

While it doesn't bring the mechanism up to contemporary standards, it does change the running qualities from "annoyingly rattly" to "decent runner".